The rocking sluice, also known as a shaking sluice or reciprocating sluice, is a highly efficient gravity separation device primarily used in the roughing and scavenging stages of mineral processing. It is especially effective for recovering fine and ultra-fine heavy minerals such as gold, tin, tungsten, platinum, hematite, and ilmenite from alluvial or placer deposits. Its ability to capture particles as fine as 20-30 microns makes it indispensable for materials that challenge traditional sluice boxes.

This equipment is a staple in alluvial gold processing plants and beach sand mineral recovery lines. It is commonly integrated into mobile or stationary wash plants, often working in conjunction with trommel screens, centrifugal concentrators, and shaking tables to form a complete recovery circuit, maximizing the yield of valuable heavy minerals.

The working principle combines the stratification effect of traditional sluices with a controlled lateral shaking motion. Pulsating water flows through the sluice box, which is mounted on a rocking frame. This rhythmic, back-and-forth motion creates a fluidized bed and enhances shear forces. Dense heavy minerals settle and are trapped behind riffles (or on special mats), while lighter gangue materials are washed away downstream. The key advantages include significantly higher recovery rates for fine gold compared to static sluices, relatively low water consumption, simple operation, low maintenance costs, and high capacity per unit area. It is a robust, energy-efficient solution with a high concentration ratio.

Regarding its structure, the main components are:

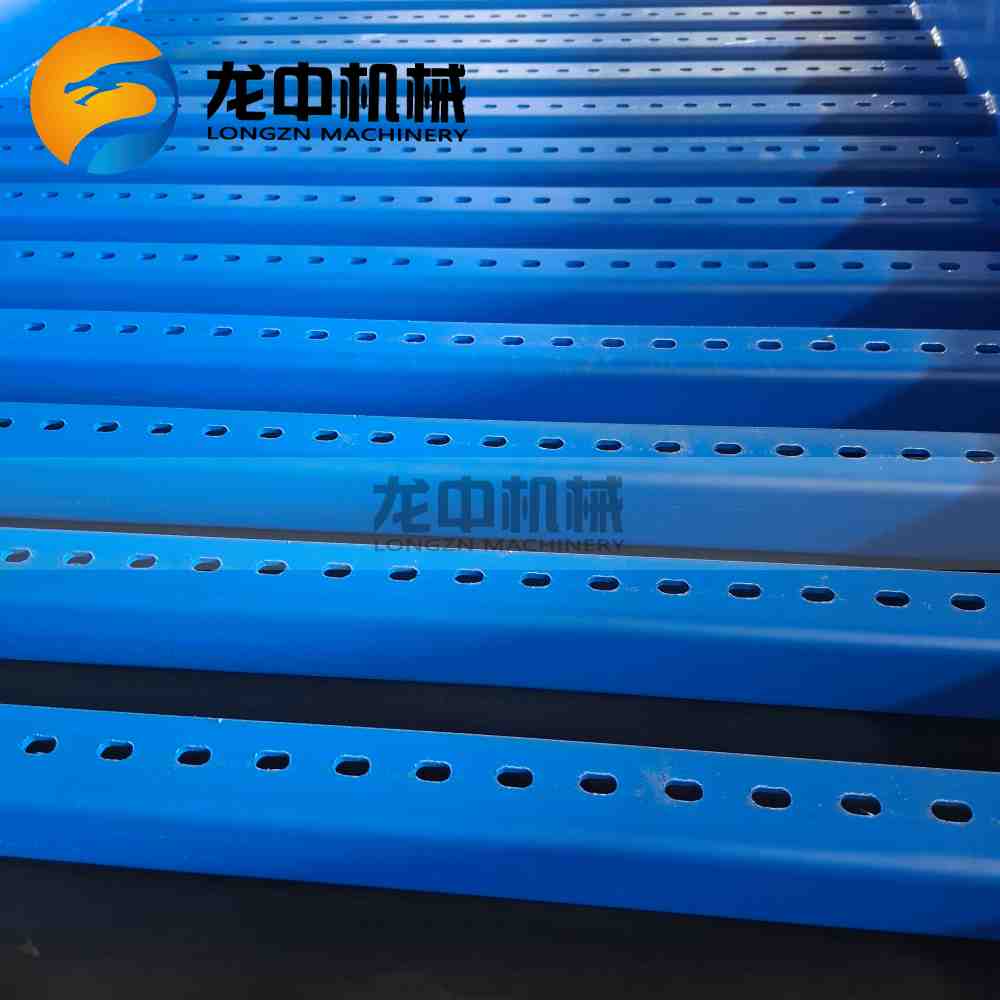

Sluice Box/Trough: A long, inclined channel lined with riffles, carpets, or astroturf to trap heavy minerals.

Rocking Mechanism: Usually consisting of an eccentric drive or crank system that provides the controlled reciprocating motion.

Frame/Support Structure: A sturdy base that supports the sluice and the rocking mechanism.

Feed Box/Distributor: Ensures an even distribution of the feed slurry across the width of the sluice.

Discharge Launder: Channels the tailings (waste) away from the concentrating zone.

This simple yet effective design makes the rocking sluice a reliable workhorse in gravity concentration circuits worldwide.