The three-roller magnetic separator is a highly efficient dry high-intensity magnetic separator (DHIMS). It is primarily employed in the cleaning and purification stage of mineral processing, specifically for removing weak magnetic impurities or concentrating weakly magnetic minerals. It is exceptionally effective for processing non-metallic minerals such as quartz, feldspar, nepheline syenite, calcite, and kaolin, where even trace amounts of iron-bearing impurities (like biotite, hematite, or ilmenite) can severely degrade product quality and value.

This equipment is a staple in industrial mineral processing lines, most commonly found in quartz sand and feldspar beneficiation plants. Here, it plays a critical role in producing high-purity, low-iron raw materials essential for the glass, ceramics, and electronics industries.

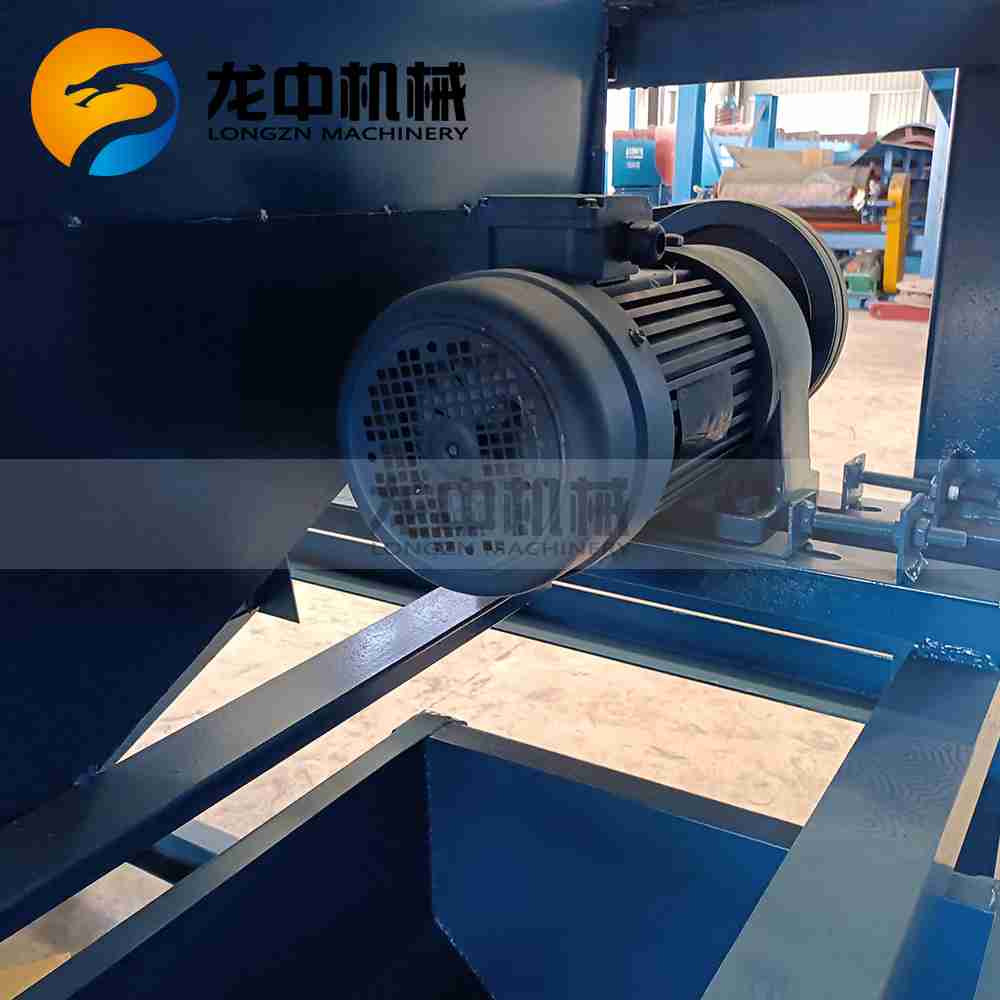

Its working principle relies on creating a high-gradient magnetic field across three consecutive rolls. As the mineral powder is fed onto the first roll, magnetic particles are attracted and pinned to the rotating roll surface, while non-magnetics are thrown off by centrifugal force. The captured magnetics are transferred to subsequent rolls with even higher field intensities for further cleaning. The key advantages and features include a multi-stage purification process for superior product purity, high separation efficiency for fine materials, a completely dry operation eliminating water usage and sludge, easy adjustment of magnetic intensity and roll speed, and generally lower operational costs compared to wet methods.