Asymmetry of Motion

The asymmetry of the shaking table motion significantly affects the selective longitudinal transport of ore particles and the loosening of the bed layer. An appropriate degree of asymmetry should ensure both effective selective transport and adequate bed loosening. For coarse materials that are relatively difficult to loosen but easier to transport, a lower asymmetry may be used. For fine materials that are harder to move, a higher asymmetry is recommended.

Stroke Length and Frequency

These parameters directly determine the speed and acceleration of the bed surface motion, thereby significantly influencing bed loosening, stratification, and selective transport. The final stroke length and frequency should promote good stratification and strong selective transport. For coarse materials, cleaning operations, or high-load conditions, a large stroke length and low frequency are generally adopted, with a stroke length of 16–30 mm and a frequency of 200–250 cycles/min. For fine materials, roughing operations, or low-load conditions, a small stroke length and high frequency are preferred, typically with a stroke length of 8–10 mm and a frequency of 250–300 cycles/min.

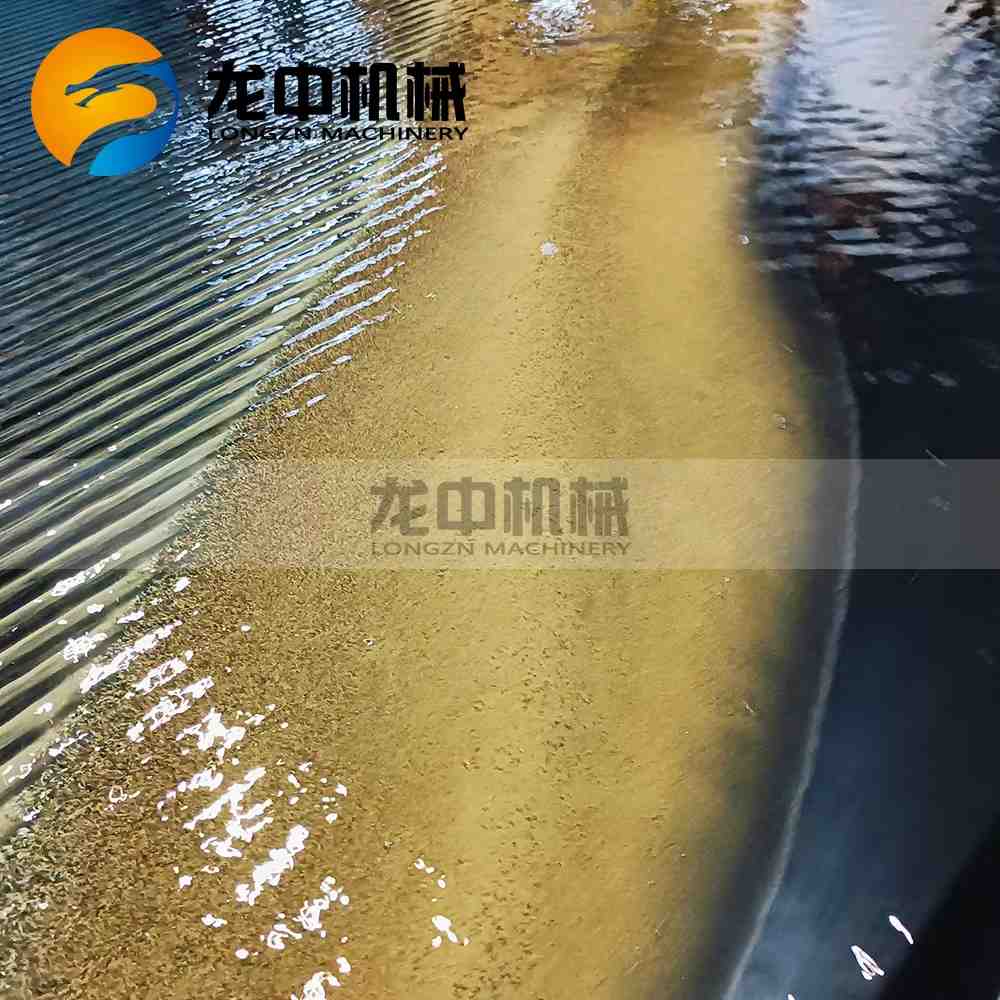

Water Volume and Deck Slope

Both factors affect the transverse flow velocity and water layer thickness on the deck, determining the speed of transverse particle transport and the intensity of cleaning. These are frequently adjusted during operation. Increasing the slope reduces the required water volume, and vice versa. Increasing water volume while reducing the slope thickens the water layer. Proper coordination between water volume and slope is essential in operation. For coarse materials, refractory ores, and cleaning operations, higher flow velocity and thinner water layers are required, achieved by using a steeper slope and lower water volume. Typically, the inclination angle ranges from 0° to 10°, and the water volume is 20–50 L/min.

Feed Volume and Feed Concentration

Both parameters influence stratification and transport speed. Excessive feed volume leads to a thicker bed layer, poorer stratification, increased transport speed, higher tailings grade, and reduced recovery. Insufficient feed volume significantly reduces processing capacity. Excessive slurry concentration may result in sand accumulation, while overly dilute concentration can cause channeling. Feed volume and concentration must be well-coordinated. The guiding principle is to select the optimal feed concentration within the allowable feed volume range. Generally, feed concentration ranges from 15% to 25%, with higher values for coarse particles and lower values for fine particles. When processing sand ores above 0.2 mm, the production capacity is 0.7–2.3 tons per table per hour. For fine materials below 0.2 mm, the capacity is 0.2–0.5 tons per table per hour.

Feed Particle Size and Shape

These factors affect the accuracy of density-based separation. Therefore, pre-concentration processes such as classification, desliming, and degritting are essential. Overly coarse and rounded heavy particles not only interfere with the separation of fine particles but are also prone to loss in tailings. If coarse and rounded particles are gangue, they may facilitate separation. Extremely fine slimes are difficult to settle and are easily lost in tailings. Classified materials with uniform particle size are easier to operate and adjust, allow reasonable load distribution between coarse and fine shaking tables, and contribute to improved production capacity.