The ball mill is a fundamental piece of equipment in the mineral processing industry, primarily employed in the grinding stage following initial crushing. It serves as a key unit operation for comminution, reducing ore particles to a fine size to liberate valuable minerals from the gangue. This versatile machine can process a vast array of minerals, including but not limited to copper, gold, iron ore, lead-zinc, molybdenum, and phosphate rock, as well as industrial minerals like quartz and feldspar. Its applicability extends to both metallic and non-metallic ores.

Ball mills are a core component in numerous beneficiation production lines. They are universally found in flotation plants where fine grinding is essential for achieving optimal mineral liberation and subsequent separation. They are also integral to magnetic separation lines for iron ore, cyanidation (leaching) circuits for gold extraction, and gravity concentration plants. In essence, any flowsheet requiring the reduction of ore to a finely ground slurry (pulp) for further processing will likely feature a ball mill.

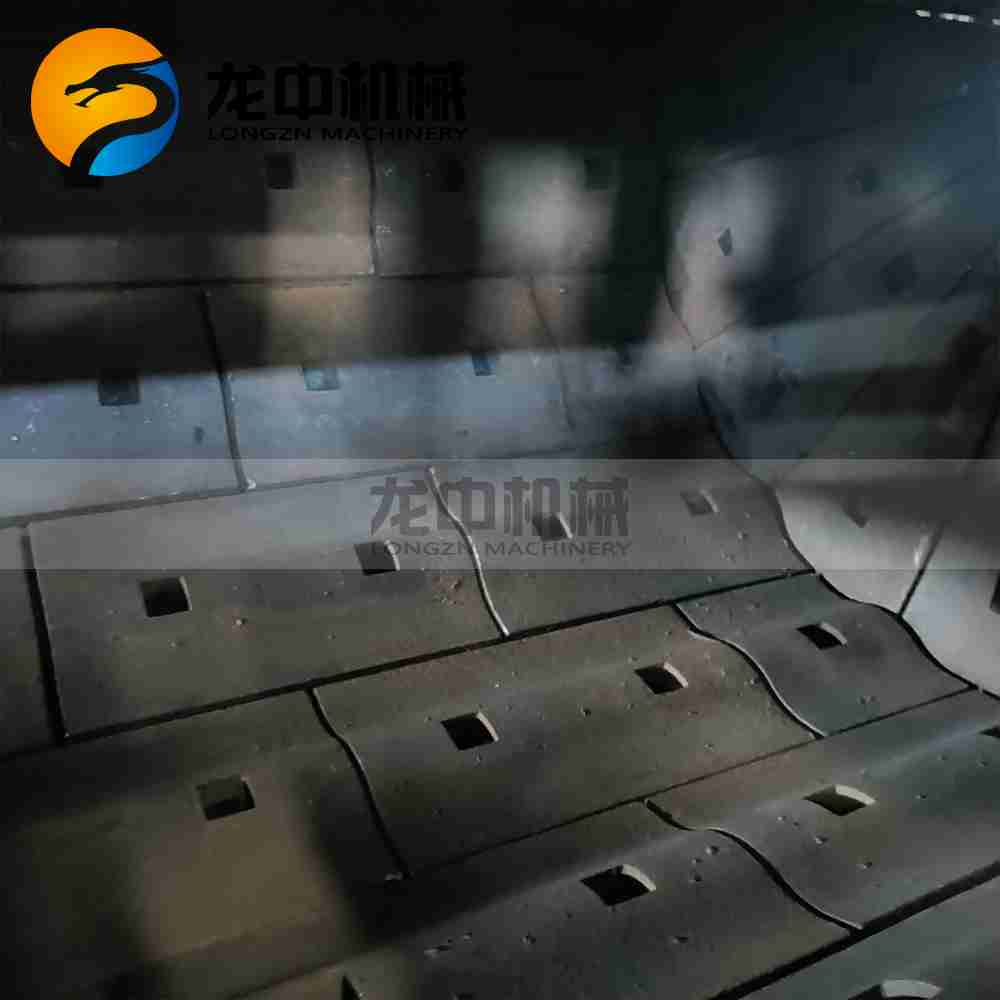

The working principle is relatively straightforward: the mill rotates around a horizontal axis, partially filled with the material to be ground and the grinding media (steel or ceramic balls). As the shell rotates, the balls are lifted and then cascade or cataract down onto the ore, impacting and abrading it through a combination of forces to achieve pulverization. The key advantages of ball mills include:

High versatility and wide applicability.

Robust construction and reliable operation.

Ability to produce a fine product with a relatively uniform particle size distribution.

Capability for both wet and dry grinding, though wet grinding is more common for mineral processing due to easier material handling and reduced dust.

Adaptability to continuous operation in large-scale industrial settings.