In mineral processing, the mining agitation tank, or stirring tank, is primarily utilized in the mixing and conditioning stages prior to separation processes such as flotation or leaching. It is designed to handle slurries of various minerals, including but not limited to gold, copper, zinc, lead, iron ore, and phosphate. Its purpose is to ensure uniformity in pulp density and chemical reagent distribution.

This equipment is a common and essential component in several key processing lines, most notably in flotation plants and cyanide leaching circuits for gold extraction. It is also frequently integrated into hydrometallurgical processes and various mixing and storage applications within beneficiation flowsheets.

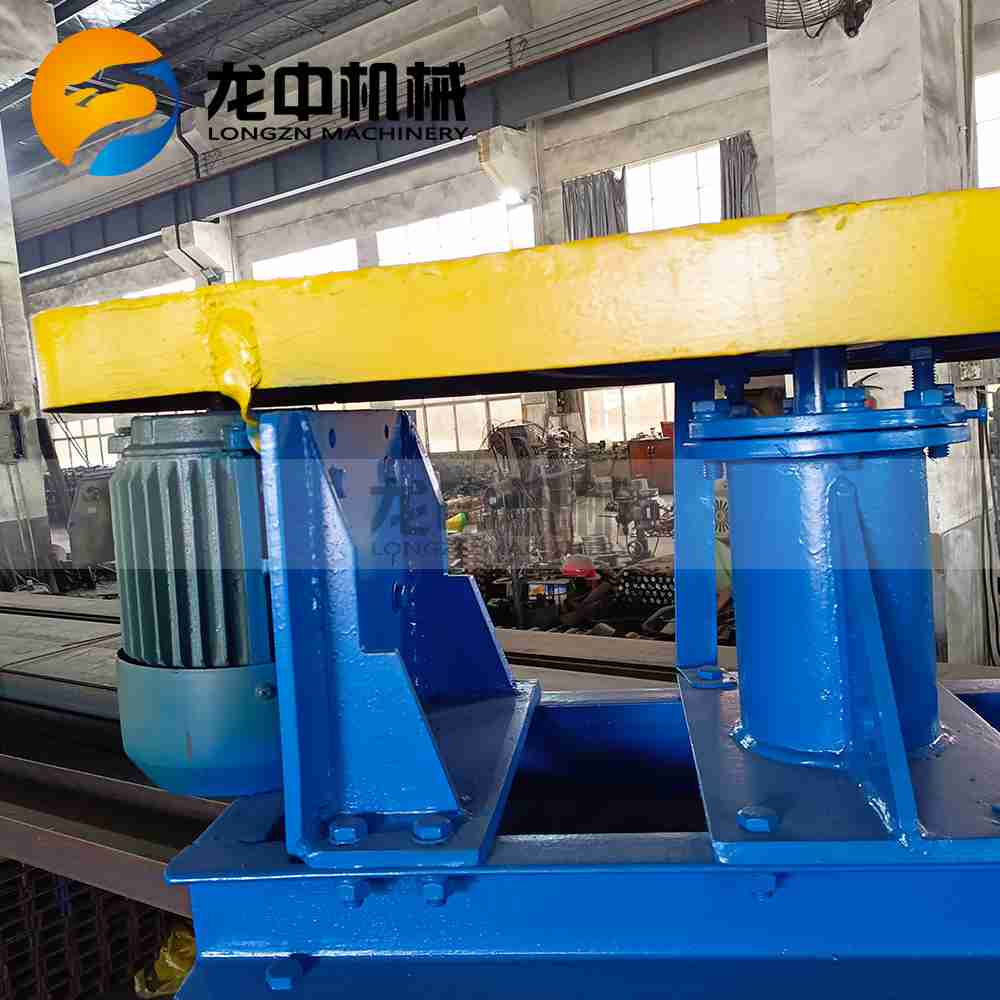

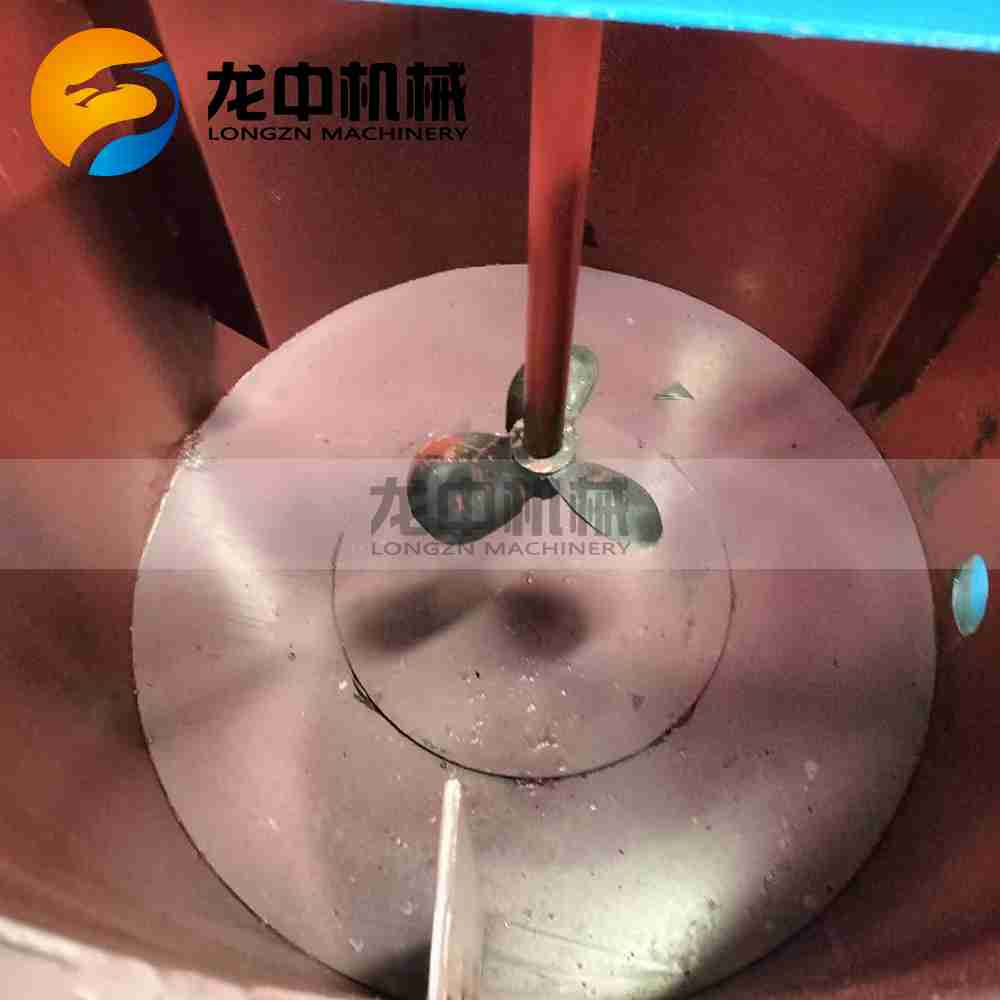

The core working principle involves using a rotating impeller driven by an electric motor to create intense agitation within the tank. This action keeps solid particles in suspension, prevents sedimentation, and promotes thorough contact between ore particles, chemicals, and air (if required). Its key advantages include strong mixing performance, reliable operation, simple structure for easy maintenance, and effectiveness in creating a homogeneous pulp, which is critical for downstream process efficiency.