In nature, ilmenite resources can be categorized into two main types based on their geological characteristics: primary ilmenite and placer ilmenite.

Primary ilmenite is often associated with titanomagnetite or vanadium-titanium magnetite. Its key features include large and concentrated reserves, making it suitable for large-scale mining. However, it typically has a high gangue content, low recovery rates, and poor processability.

Placer ilmenite is a secondary deposit. It is characterized by a loose structure and better processability, but the run-of-mine ore has a low grade and is prone to sliming.

Therefore, the different characteristics of ilmenite ores impose different requirements on the beneficiation methods used. Currently, the common primary beneficiation methods for ilmenite include gravity separation, magnetic separation, electrostatic separation, flotation, and combined methods.

I. Gravity Separation for Ilmenite Recovery

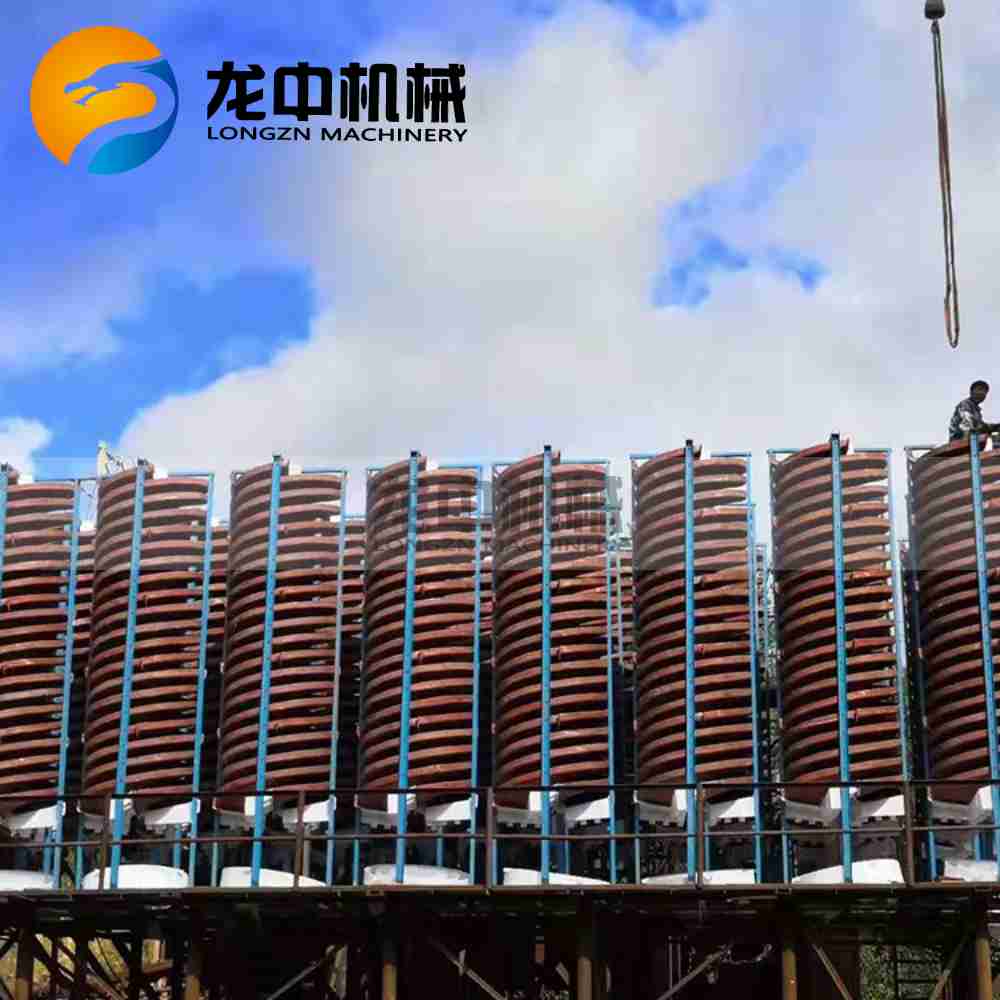

Gravity separation is suitable for coarse-grained disseminated and fine-grained aggregated disseminated ilmenite. After primary and secondary crushing, gravity separation equipment, such as spiral chutes and shaking tables, can be used to discard a significant amount of gangue and remove slime.

II. Magnetic Separation for Ilmenite Recovery

Ilmenite is a weakly magnetic mineral. Its specific magnetic susceptibility and density are both higher than those of gangue minerals. For minerals of the same particle size, ilmenite has a much greater volume magnetic susceptibility than gangue minerals. Consequently, during magnetic separation under a specific field strength (strength and direction of the magnetic field), gangue minerals and some fine iron silicate minerals in the ilmenite ore can easily be discarded into the tailings. High-intensity magnetic separation can effectively separate ilmenite from gangue minerals, achieving the enrichment of titanium metal and allowing the processing of ilmenite that is difficult to concentrate by gravity separation. It is commonly used in cleaning and tailing discarding stages.

III. Flotation for Ilmenite Recovery

Flotation, known for its high separation accuracy and effectiveness, is primarily used in the cleaning stage of primary ilmenite or for processing fine-grained ilmenite. Methods include conventional flotation, flocculation flotation, and agglomeration flotation.

Conventional Ilmenite Flotation: Common collectors used in conventional ilmenite flotation include oleic acid and its soaps, oxidized paraffin soap, tall oil, and newer collectors such as TAO, R-2, H1717, ZY, RST, and TOB. Among these, oleic acid and its soaps are commonly used ilmenite collectors, with mature and reliable technology. Their collecting performance can be improved by heating, increasing oxygen content, or adding emulsifiers. The disadvantages are high reagent consumption and poor selectivity. Oxidized paraffin soap, a product of paraffin oxidation and saponification, is widely available and low-cost, making it a potential substitute for oleic acid. However, it requires emulsification at room temperature to enhance its collecting effect, and often yields concentrates with lower and unstable grades.

Ilmenite Flocculation Flotation:

Flocculation flotation mainly includes selective flocculation and hydrophobic flocculation.

Selective flocculation is a method that causes one mineral to coagulate and flocculate from a dispersed system containing two or more minerals.

Hydrophobic flocculation refers to the phenomenon where hydrophobic particles suspended in water attract and agglomerate into clusters due to mutual hydrophobic interactions. Hydrophobic flocs are formed by adding collectors and neutral oil under high-speed agitation. Ilmenite flocculation flotation involves selectively flocculating fine ilmenite particles by adding flocculants like polyacrylamide, forming flocs that are then recovered by flotation.

Ilmenite Agglomeration Flotation:

Ilmenite agglomeration flotation is a technique where collectors adsorb onto the ilmenite surface, rendering it hydrophobic. Capillary attraction from liquid bridges then causes the particles to agglomerate, allowing the entire mass to float for separation. Intense agitation during agglomeration flotation is crucial, as it imparts more energy to the particles, overcoming the energy barrier between them, leading to surface hydrophobicity and subsequent flocculation/agglomeration, ultimately achieving the goal of ilmenite beneficiation.

IV. Electrostatic Separation for Ilmenite Recovery

Electrostatic separation is primarily used to process rough concentrates obtained from gravity or magnetic separation that contain non-conductive impurities like titanaugite. It is widely applied in the cleaning stage. Electrostatic separation has requirements for ilmenite particle size, with a lower limit of 0.04mm. Pre-treatment such as heating or irradiation is necessary before electrostatic separation to ensure smooth operation, avoid unnecessary issues, and improve the technical efficiency of the separation process.

V. Combined Methods for Ilmenite Recovery

Using combined methods often yields better recovery results than single methods. Primary combinations include magnetic-flotation, gravity-flotation, magnetic-gravity, and gravity-magnetic-flotation-electrostatic separation.

For the magnetic-flotation combined method, recovering ilmenite micro-fines has always been a key focus and challenge. Flotation can basically recover ilmenite down to -0.02mm, but large amounts of gangue like quartz can affect flotation performance. Pre-discarding tailings using high-intensity magnetic separation can improve the flotation environment.

The gravity-flotation combined method primarily involves roughing and cleaning using gravity equipment like spiral chutes and shaking tables to obtain qualified rough concentrate. This is followed by flotation to remove sulfur, ultimately yielding titanium concentrate and sulfur concentrate, enabling comprehensive utilization of mineral resources.

For the magnetic-gravity combined method, while placer ilmenite can be enriched by simple gravity or magnetic separation alone, the combined method often achieves better indicators while reducing costs.

For ores where the primary gangue consists of titanaugite and plagioclase, and also contains sulfide minerals, the gravity-magnetic-flotation-electrostatic combined process can be used: gravity separation discards plagioclase, flotation removes sulfur, and electrostatic separation removes titanaugite.

In summary, the choice of ilmenite beneficiation method depends primarily on the properties of the feed material. Because titanium minerals have a higher specific gravity compared to non-metallic gangue minerals, gravity separation can be used for pre-treatment or roughing to discard tailings, and can also be used to concentrate ilmenite where the gangue has a relatively lower specific gravity. Magnetic separation is widely used for iron removal operations to improve the concentrate grade of ilmenite. Electrostatic separation is mostly used for purification when titanium concentrates obtained from other processes contain various non-conductive minerals. Flotation is more suitable for processing fine-grained primary ilmenite ores. Combined beneficiation methods can fully leverage the advantages of each individual method based on the ore properties of the specific ilmenite, thereby ensuring ideal beneficiation indicators and economic benefits.

Due to the complex nature of ilmenite minerals and the significant variations in different ore properties, appropriate beneficiation processes and equipment must be determined through beneficiation tests to guarantee the actual production's beneficiation results.